Latest News

-

14 November 2023

14 November 2023

New topsheet material in stock November 2023

New Topsheet materials in stock November 2023

Read More -

04 October 2022

04 October 2022

CNC Multicutter v2 - CNC Router with optional blade cutter

The CNC Multicutter is our new CNC router with optional blade cutting attachment for die cuts.

Read More -

26 September 2022

26 September 2022

New material in stock September 2022

New Epoxy kits and red base in stock September 2022

Read More

Tip Fill - Inner material for skis and snowboards

on October 24, 2014At Action Sports we carry a variety of tip fill material including Durasurf and ABS types

Skateboard Press - SK-3000

on October 22, 2014Our new SK-3000 40 ton Longboard and Skateboard press sets the new price/performance standard...

SnoCAD software overview

on October 21, 2014SnoCAD-X software overview

This video features a brief overview of SnoCAD-X ski and snowboard CAD design software. SnoCAD-X is available from Grafsnowboards.com or you can email us and we can send you the runtime files - see our contact page for details on how to reach us.

Link to download SnoCAD-X software:

https://drive.google.com/drive/folders/0B1hkGbXDC4QqaGxIWjhubTBvXzQ?usp=sharing

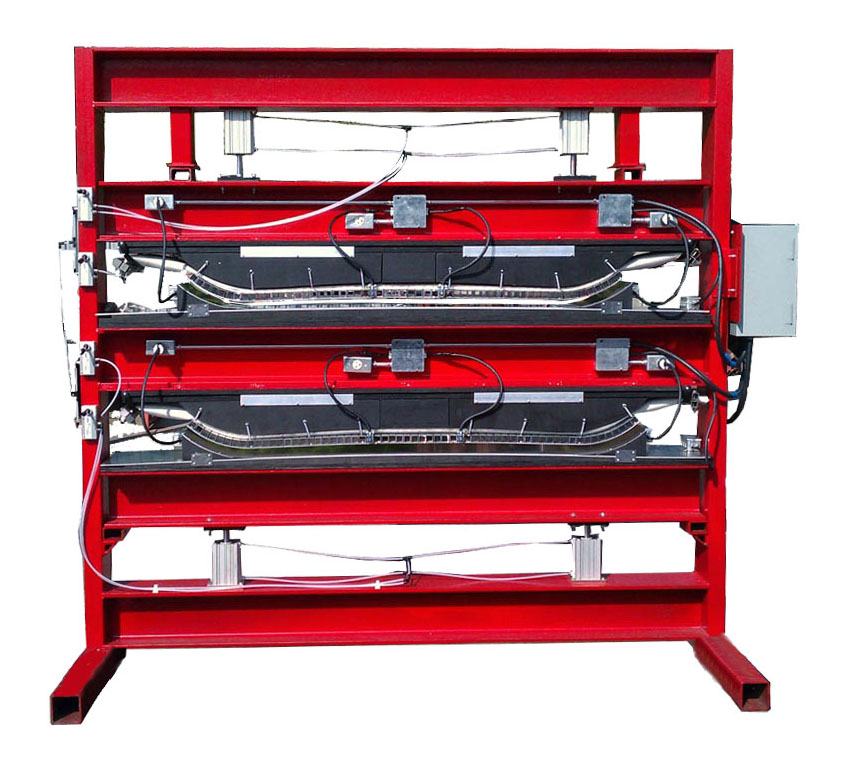

IF-3000 DC/LC - Ski and Snowboard Press

on October 14, 2014Need more capacity in a limited space? Don't have the budget for 2 separate presses? The IF-3000 DC/LC is the answer. The IF-3000 DC/LC is our top of the line dual cavity ski and snowboard laminating press.

It is for the demanding user that the needs the utmost capacity. Press 2 snowboards or 2 pair of skis at the same time in the same press. This press is our most fully featured dual cavity production laminating press that is based on the presses Lindsay designed for Powderstick Snowboards, Option Snowboards and dozens of other companies since the mid 1980's. It features heated top and bottom forms that are controlled by a digital PID control unit that allows various ramp and heat cycles to be programmed or simple set temperature operation.

The daily capacity of the IF-3000 DC/LC is dependent on the operating temperature and the cure time of the resin system used. Typically this is 6 - 8 boards per hour (3-4 per cavity) or 4 - 6 pair of skis hour ( 2 - 3 per cavity) based on 60-70 degree C temperature using the Action Sports Extreme epoxy system and depending on the complexity of the layup. Other epoxies will vary in terms of cure time and can allow faster or slower cure cycles and resin pot life.

This machine features an all steel I-beam "Lift Cylinder" frame design (hence the LC designation) that enables us to make a very stiff, high performance frame when space and weight are not as much of a concern. The Lift Cylinder frame design allows the operator to lift the top beam up approximately 75mm in addition to the normal cavity opening when not inflated to allow super easy cleaning, loading and adjustments. This is where the LC design shines, as often times loading, cleaning, maintenance and size adjustments can take a lot of time. The lift cylinder design allows easier access and saves time in all these areas.

The IF-3000 DC/LC ski and snowboard press features an all pneumatic "air bladder/caterpillar track" top form assembly for unlimited ski or board thickness profiles, adjustable length, various camber and rocker profiles and more (1 rocker/camber profile included, others can be ordered).

Standard Specifications (we can build to other specs please inquire):

- Dual cavity design - press 2 snowboards or 2 pair of skis at once

- All steel "Lift Cylinder" I-beam frame design that opens up for easy loading, cleaning and maintenance on each cavity

- Adjustable for different lengths (standard from 140cm to 175cm - other size ranges available)

- Heated all aluminum top and bottom forms

- Digital temperature control

- Modular tip, tail, and camber/rocker "form blocks" can be interchanged for different profiles (steep/mellow nose and tail, camber/rocker/hybrid etc)

- 355mm standard width (other widths available)

- All aluminum "caterpillar track" top form assembly works as a flexible caul plate for unlimited thickness profiles

- dual 600lb burst air bladders

- 220v single phase 45 amps - other configurations available

- 96" long x 40" wide x 90" tall x approximately 2200lbs in standard form

Typical 220 volt single phase configuration $20,995. Other options, custom dimensions and International electronics are available, please inquire.

Note: our machines are not UL rated. We use use UL, CE and CSA components throughout but do not represent the machines to be certified as UL rated or otherwise.

IF-2500 DFC/S - Ski and Snowboard Press

on October 14, 2014So you want an all in one ski/snowboard lamination press that also features a built in sublimation heat press? Our IF-2500 DFC/S is the answer.

IF-2000 LC - Ski and Snowboard Press

on October 14, 2014Time is Money and the IF-2000 LC is designed to be fast. The IF-2000 LC is our high end single cavity ski and snowboard laminating press.

IF-2000 FC - Ski and Snowboard Press

on October 14, 2014The IF-2000 FC is our mid range production ski and snowboard laminating press.

SnoCAD to Sheetcam to Mach 3

on October 12, 2014SnoCAD to SheetCAM to Mach3

This video demonstrates basic setup and export of various ski or snowboard files from Snocad to Sheetcam for cutting parts or templates on the Action Sports Technology CNC Multicutter or similar CNC router.

Printed Topsheets and Bases original

on October 12, 2014Action Sports/SnowboardMaterials.com can print top quality, high resolution graphics on your topsheet and base material ensuring your boards and skis have that professional look. We use the same printing equipment and only use top quality materials such as LAES, Durasurf, Isosport and other leading brand names.

Machinery for Extreme Sports Manufacturing

on October 05, 2014At Action Sports we specialize in all aspects of extreme sports manufacturing and technology.

We have been building and selling machines and equipment for the ski, snowboard, skateboard, wakeboard and other industries through the SnoboardMaterials.com and Custom-Shop.com websites for 15 years, and our company founder Lindsay Rogers has been manufacturing skis and snowboards for more than 30 years, and factories he has set up have manufactured well in excess of 100,000 snowboards.

We offer several different standard models of presses and vacuum molds and also specialize in custom built machines, so if you need something special for your designs do not hesitate to contact us so we can build something to your specifications.