It is suitable for both the medium to higher volume production user and die hard hobby/enthusiast DIY ski and snowboard builders.

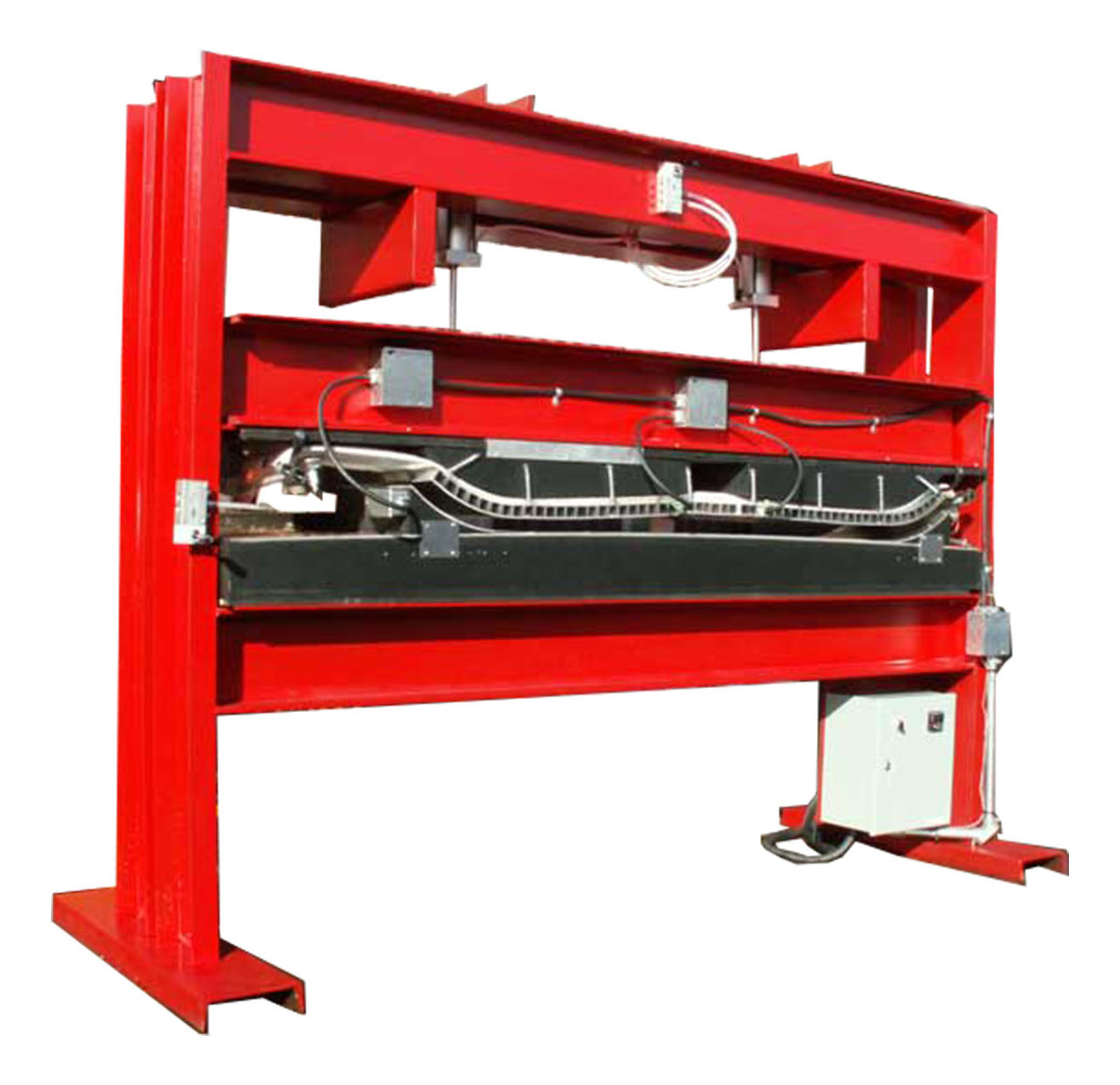

The IF-2000 LC is a high capacity production laminating press based on the presses Lindsay designed for Powderstick Snowboards, Option Snowboards and dozens of other companies since the mid 1980's. It features heated top and bottom forms that are controlled by a digital PID control unit that allows various ramp and heat cycles to be programmed or simple set temperature operation.

The daily capacity of the IF-2000 LC is dependent on the operating temperature and the cure time of the resin system used. Typically this is 3 - 4 boards per hour or 2 - 3 pair of skis per hour based on 60-70 degree C temperature using the Action Sports Extreme epoxy system - other epoxies will vary in terms of cure time and can allow for faster or slower cure cycles and resin pot life.

This machine features a fully featured all steel I-beam "Lift Cylinder" frame design (hence the LC designation) that enables us to make a very stiff, high performance frame when space and weight are not as much of a concern. The Lift Cylinder frame design allows the operator to lift the top beam up approximately 75mm in addition to the normal cavity opening when not inflated to allow super easy cleaning, loading and adjustments. This is where the LC design shines, as often times loading, cleaning, maintenance and size adjustments can take a lot of time. The lift cylinder design allows easier access and saves time in all these areas.

The IF-2000 FC ski and snowboard press features an all pneumatic "air bladder/caterpillar track" top form assembly for unlimited ski or board thickness profiles, adjustable length, various camber and rocker profiles and more (1 rocker/camber profile included, others can be ordered).

Standard Specifications (we can build to other specs please inquire):

- All steel "Lift Cylinder" I-beam frame design that opens up for easy loading, cleaning and maintenance

- Adjustable for different lengths

- Heated all aluminum top and bottom forms

- Digital temperature control

- Modular tip, tail, and camber/rocker "form blocks" can be interchanged for different profiles (steep/mellow nose and tail, camber/rocker/hybrid etc)

- 356mm standard width (other widths available)

- All aluminum "caterpillar track" top form assembly works as a flexible caul plate for unlimited thickness profiles

- dual 600lb burst air bladders

- 96" long x 40" wide x 72" tall x approximately 1500lbs in standard form

Typical 220 volt single phase configuration with 14" wide bed is approxmately $16,495. Prices will vary depending on exchange rates, steel and aluminum costs etc at the time of manufacture. Note that the press shown in photo has a custom 20" wide bed that would cost addtional - the 14" presses are essentially identical but narrower. Other options, custom dimensions and International electronics are available, please inquire.

Note: our machines are not UL rated. We use use UL, CE and CSA components throughout but do not represent the machines to be certified as UL rated or otherwise.