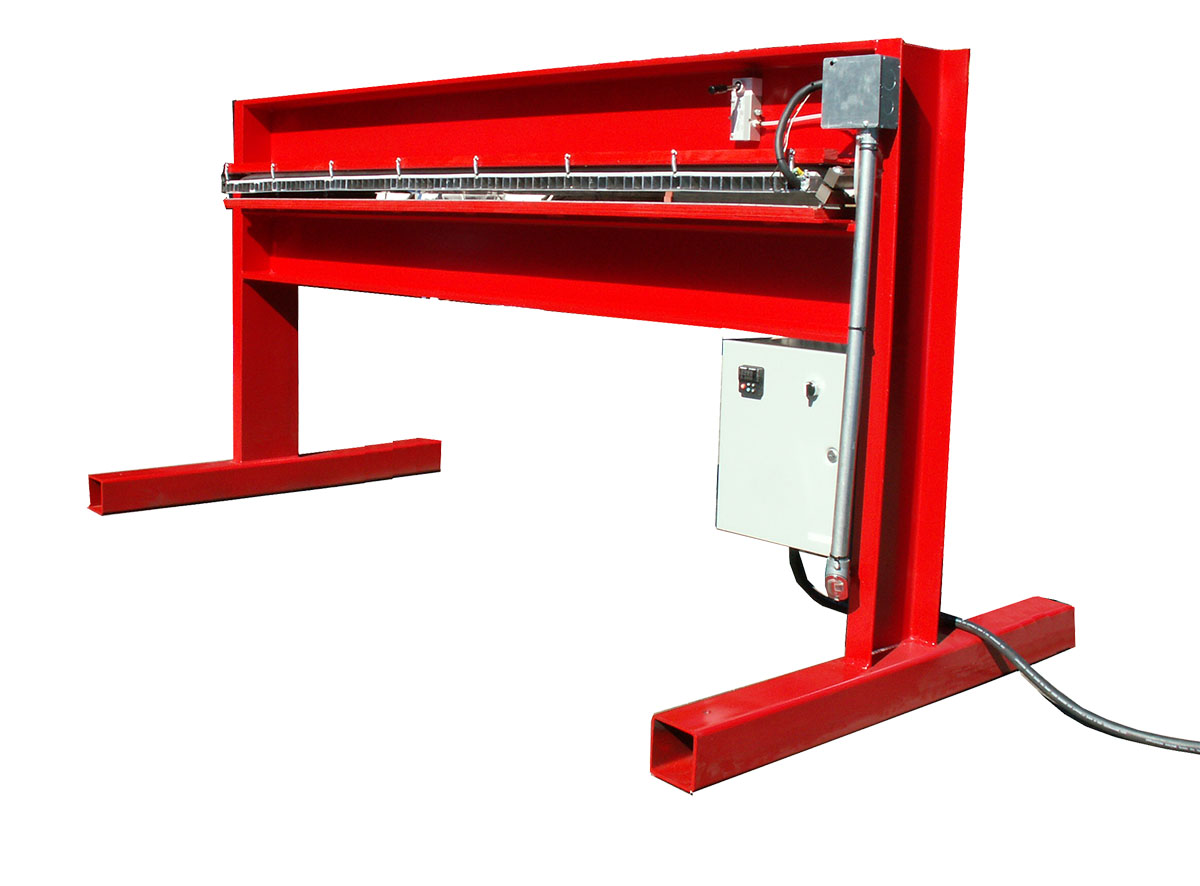

The SUB-2000 sublimation heat press features a 204cm x 35.5cm (80" x 14" approx) heated platen area that will sublimate finished sizes up to 198cm x 34cm depending on the shrinkage characteristics of the materials used. We can customize these dimensions for a minor upgrade price.

It features a custom designed heating system that is specifically designed for sublimation printing with more evenly distributed heat than standard blanket type heaters.

It comes with one specially designed sublimation cassette that features a custom, low durometer, high temperature silicone equalization coating on one side to equalize pressure for the most even transfers possible. Additional cassettes can be ordered for even faster cycling or to enable cooling cycles in the cassettes when printing certain base material and other unstable substrates (1 in the press, 1 or more cooling).

Typical transfer times range from 4 - 12 minutes per print depending on the press temperature and heat stability of the material being sublimated.

Standard Specifications (we can build to other specs please inquire):

- All steel I-beam frame design

- Heated all aluminum bottom plate with custom sublimation heater

- Digital temperature control

- 345mm standard width x 204cm length (other custom lengths and widths available)

- All aluminum "caterpillar track" top form assembly to equalize bladder pressure

- high temperature silicone and 1700 degree kiln insulation between frame, caterpillar track assembly and heated platen.

- dual 300lb burst air bladders

- 1yr parts and labor warranty

- Frame dimensions - 96" long x 40" wide x 56" tall x approximately 1100lbs in standard form. The heat transfer area is14" x 80" heat area - approx 350mm x 2032mm )

Typical 220 volt single phase configuration $11,295. Other options, custom dimensions and International electronics are available, please inquire.

Note: Our machines are not UL rated. We use UL, CE and CSA parts throughout but we do not represent the machines as UL rated or otherwise. Only certain grades and types of material can be sublimated and we recommend testing your exact combination of paper, inks and material prior to committing to production.